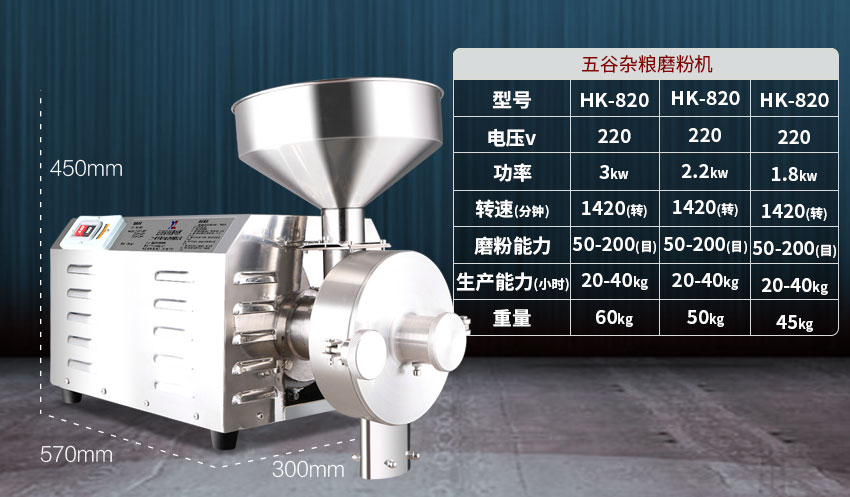

Guangzhou Xulang Machinery Co.,Ltd,which is the earliest factory specialized in manufacturing whole grains milling machine in China.Department of technology & innovation in the company always commited to improving and promoting the technology of whole grains milling machine gradually and pursuit of excellent and perfection relies on the machine performance,stable quality,smooth feeding,fineness of milling powder,reduction of noise,vibration and beautiful outlook etc.Since 820 milling machine is sold in the market,the machine is always imitated by suppliers in the same field, most of which are some small milling house.The product pictures are copied by many suppliers in the same field and dealers crazily so as to cheat customers to get more benefits.Please do pay attention to distinguishing these worse behaviors to prevent fraud.Imitation always exists,but never surpassed!

Guangzhou Xulang Machinery Co.,Ltd,which is the earliest factory specialized in manufacturing whole grains milling machine in China.Department of technology & innovation in the company always commited to improving and promoting the technology of whole grains milling machine gradually and pursuit of excellent and perfection relies on the machine performance,stable quality,smooth feeding,fineness of milling powder,reduction of noise,vibration and beautiful outlook etc.Since 820 milling machine is sold in the market,the machine is always imitated by suppliers in the same field, most of which are some small milling house.The product pictures are copied by many suppliers in the same field and dealers crazily so as to cheat customers to get more benefits.Please do pay attention to distinguishing these worse behaviors to prevent fraud.Imitation always exists,but never surpassed!

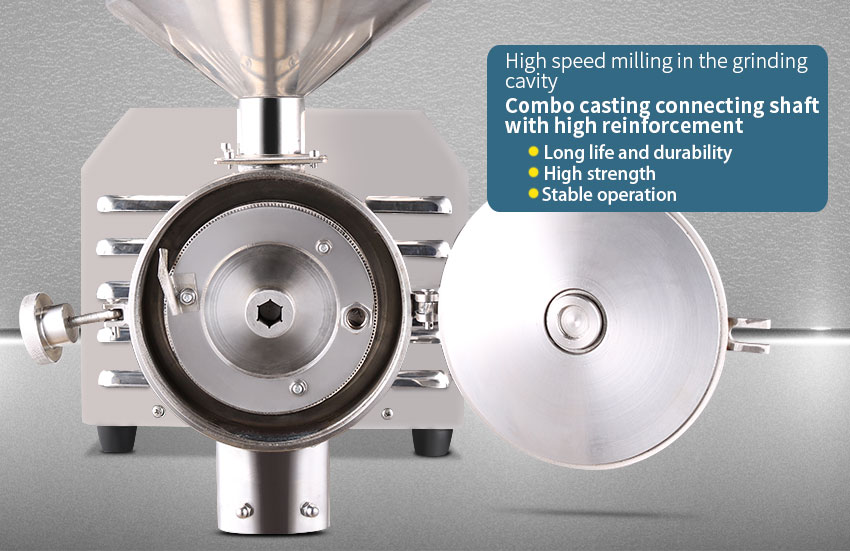

Working principle

Connecting shaft directly connects motor axis.When the motor runs,it will make connecting shaft and milling disc sleeving on the connecting shaft rotate together.When pending milling materials enter the milling powder cavity from the hopper,core shaft of milling plate and milling powder casing relatively rotate,which produces crushing ability to make materials minced into small particles.Minced small particles are brought into the middle of two milling blades under spiral motion of milling disc.With interactive motion of milling blades and gear teeth,the materials are smashed into thin small particles or powder for a short time. The powder pours out from the teeth ditch of milling blades and throws everywhere.Meanwhile,the powder discharges from the powder outlet under pushing ability of scraping powder board on the milling disc.

Features for 2012 type milling machine

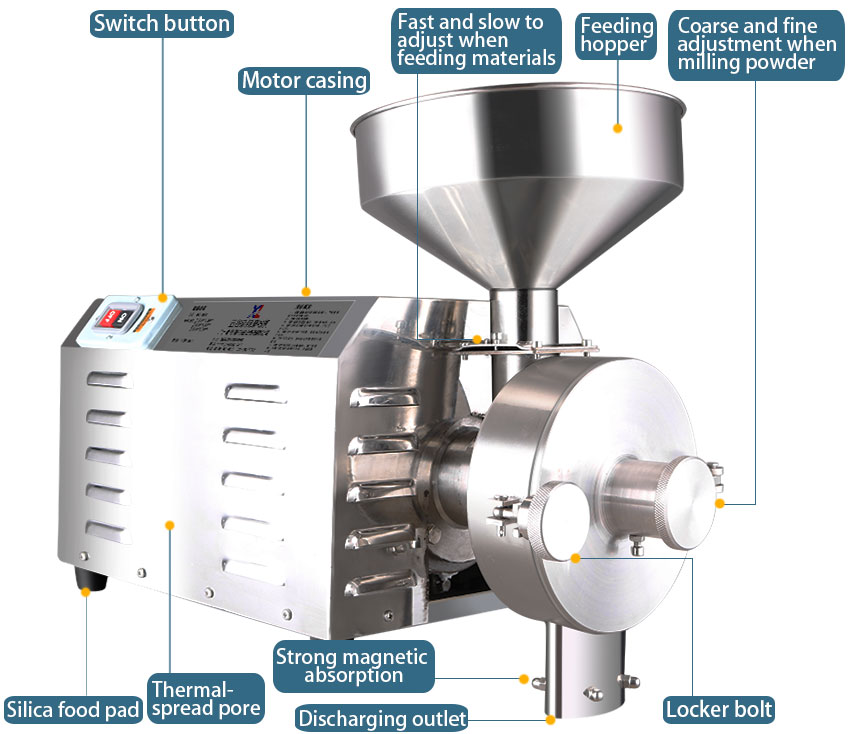

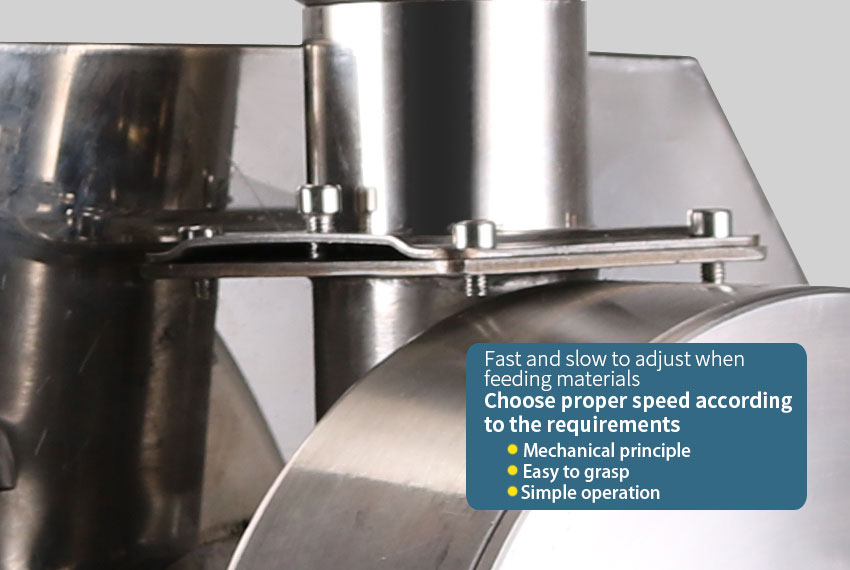

1.The regulator of new machine no longer needs firm nut to fasten and adjusts to designated position,motion of the machine never influences fixed position of regulator which no longer needs fixation.After regulator of old type machine adjusts to designated position,it needs firm nut to block inside so as to prevent regulator rotating with the machine.

2.The device with 4 strong magnetic is installed on the powder outlet.The purpose of installation is to absorb iron powder produced by milling blades abrasion during the period of machine rotation and guarantee sanitation and safety of foodstuff.

3.Connecting shaft is short,dismantlement and installation are simple and convenient.

4.Stainless steel hopper is disposably punched and formed.No soldering point,more luxurious,more beautiful and more sanitary.

5.Both sides of motor casing have six lane thermal-spread pore.One is to make use of motor to spread heat and protect motor.The other is to reduce the resonance of the container with seal-ring and achieve low vibration

TEL:4000666065